The quality of a part depends on your know-how. Mecanic makes it possible to integrate and develop this know-how. Each step of the programming is controlled and certified.

This certification is based on:

- Control and improvement of the geometry

- Definition and storage of the used technologies

- Personalization and creation of your favorite manufacturing

- Simulation and control of the produced NC Code

Advantages:

- Creation of a manufacturing program integrating all your know-how

- Guaranteed repeatability of the manufacturing

- Simple Adaptation to another type of machine

● Why MECANIC

Mecanic allows the optimal use of machining technologies, which are essential for the manufacturing of very precise mechanical components with high added value.

Technology

Each company has its standards of quality for wire erosion. These standards correspond to choices of technology on each machine.

Mecanic provides the basic technologies for each version and for each EDM machine model, such as +GF+ Machining Solution, Agie, Charmilles, Mitsubishi, Sodick, Fanuc, Makino, …

Mecanic also allows importing or create users customized technologies.

The use of the correct technologies guarantees the quality of the results.

Geometry

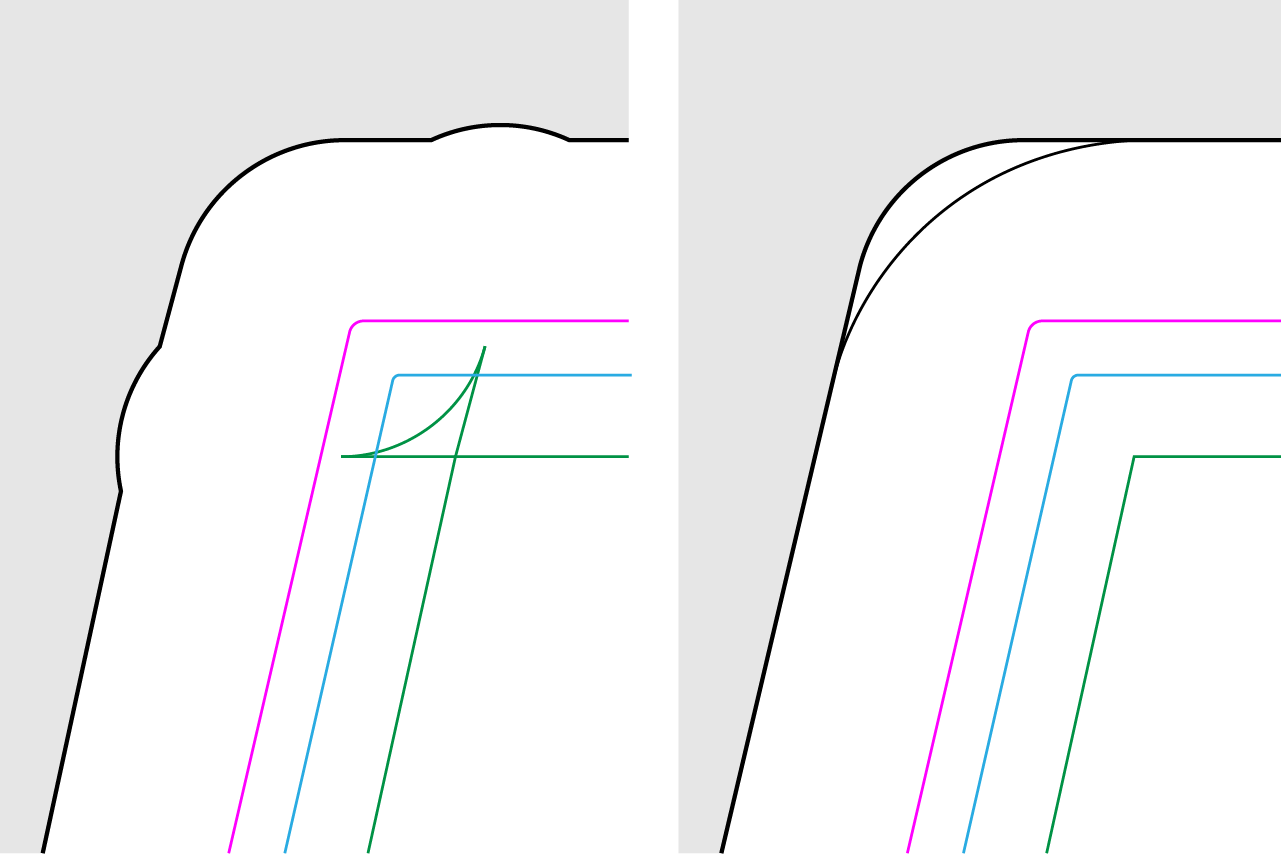

A powerful geometrical processor enables you to draw or modify any geometrical element.

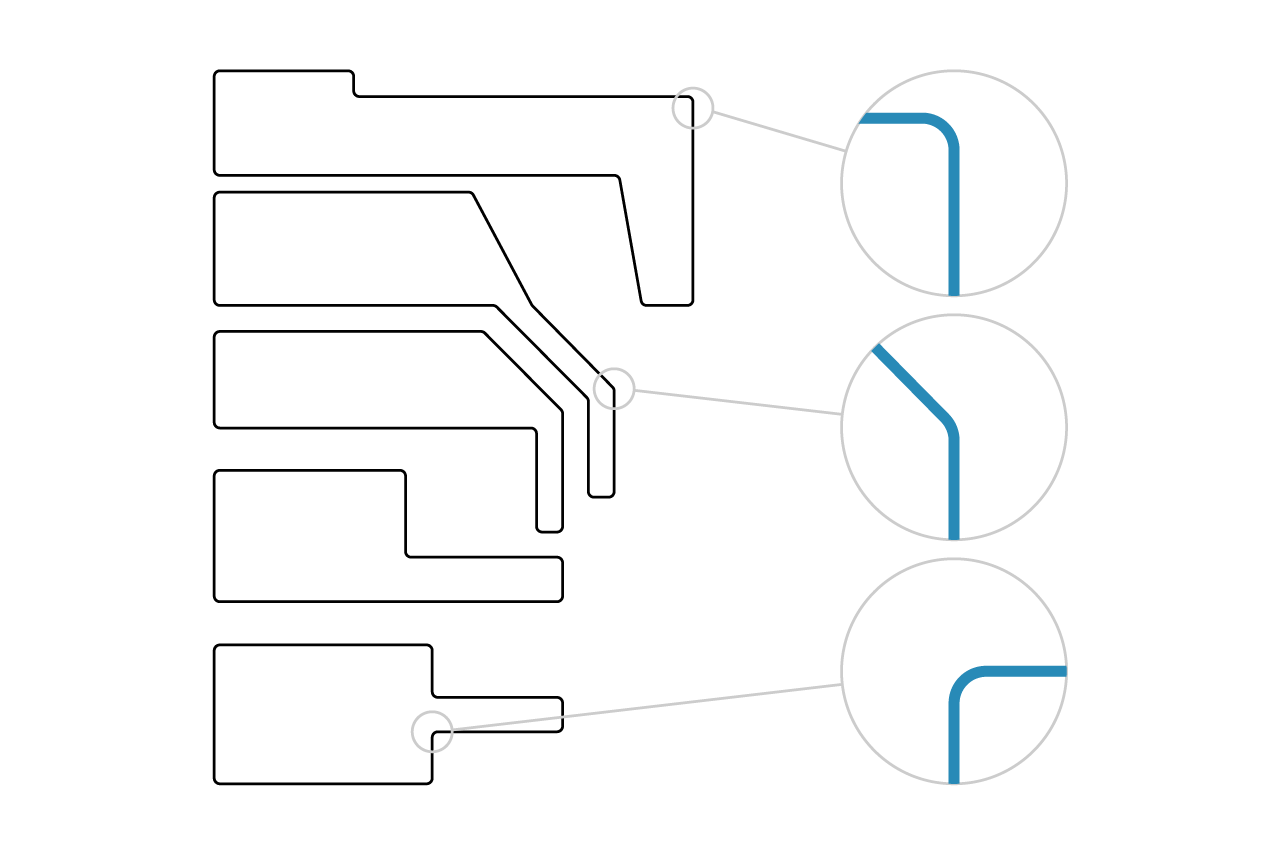

2D contours – DXF

At the time of the importation of the contours, the contours are analyzed and if necessary, thanks to simple tools, they are corrected.

As in the case of not required line intersections, not tangent elements, or missing radii.

3D contours and 3D import

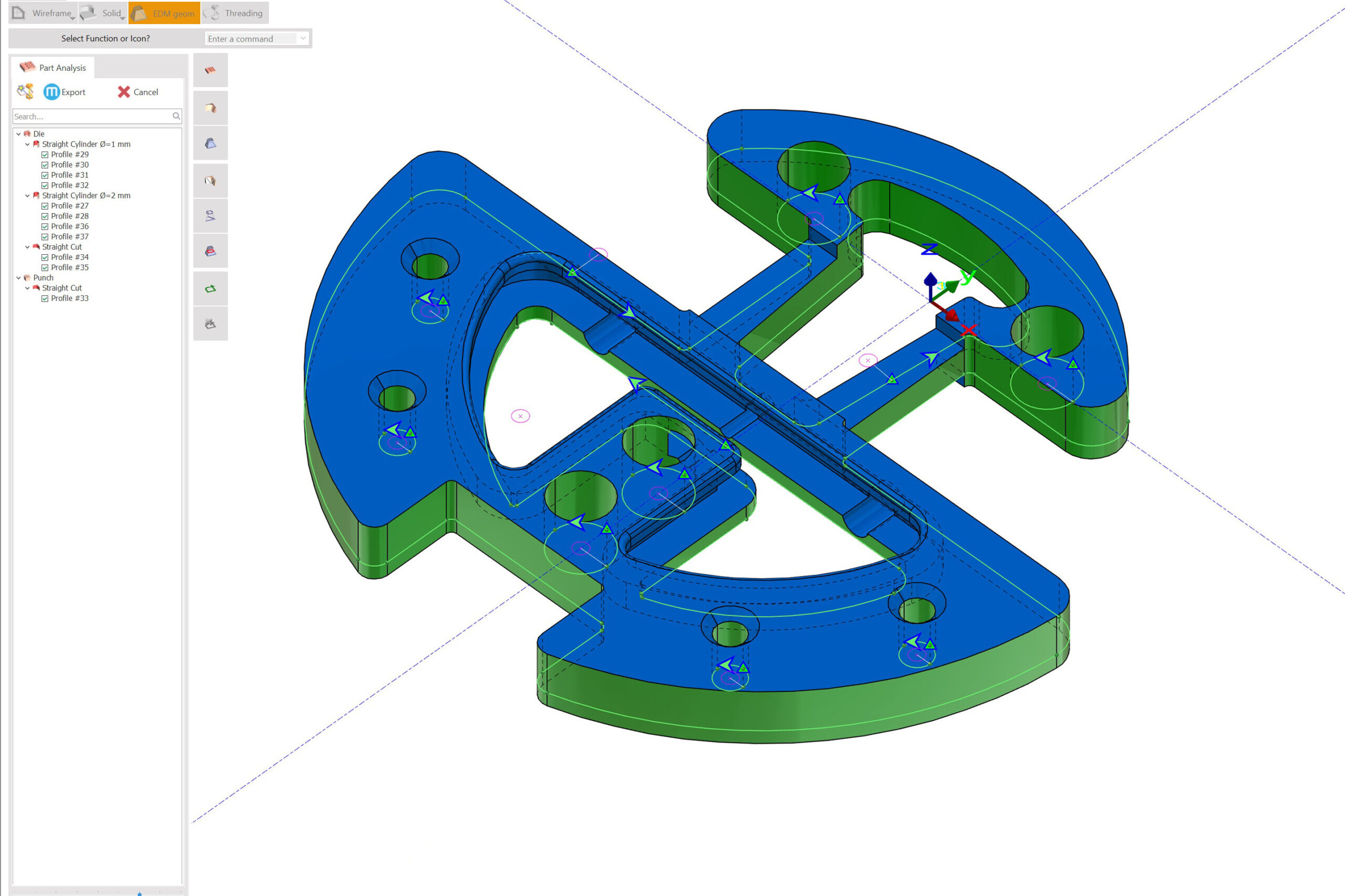

● 3D to MECANIC

GO2cam Mecanic

GO2cam Mecanic allows to import any type of 3D file, to orientate it, to position it and to transfer all the contours and/or surfaces to be work in Mecanic, in a simple and efficient way.

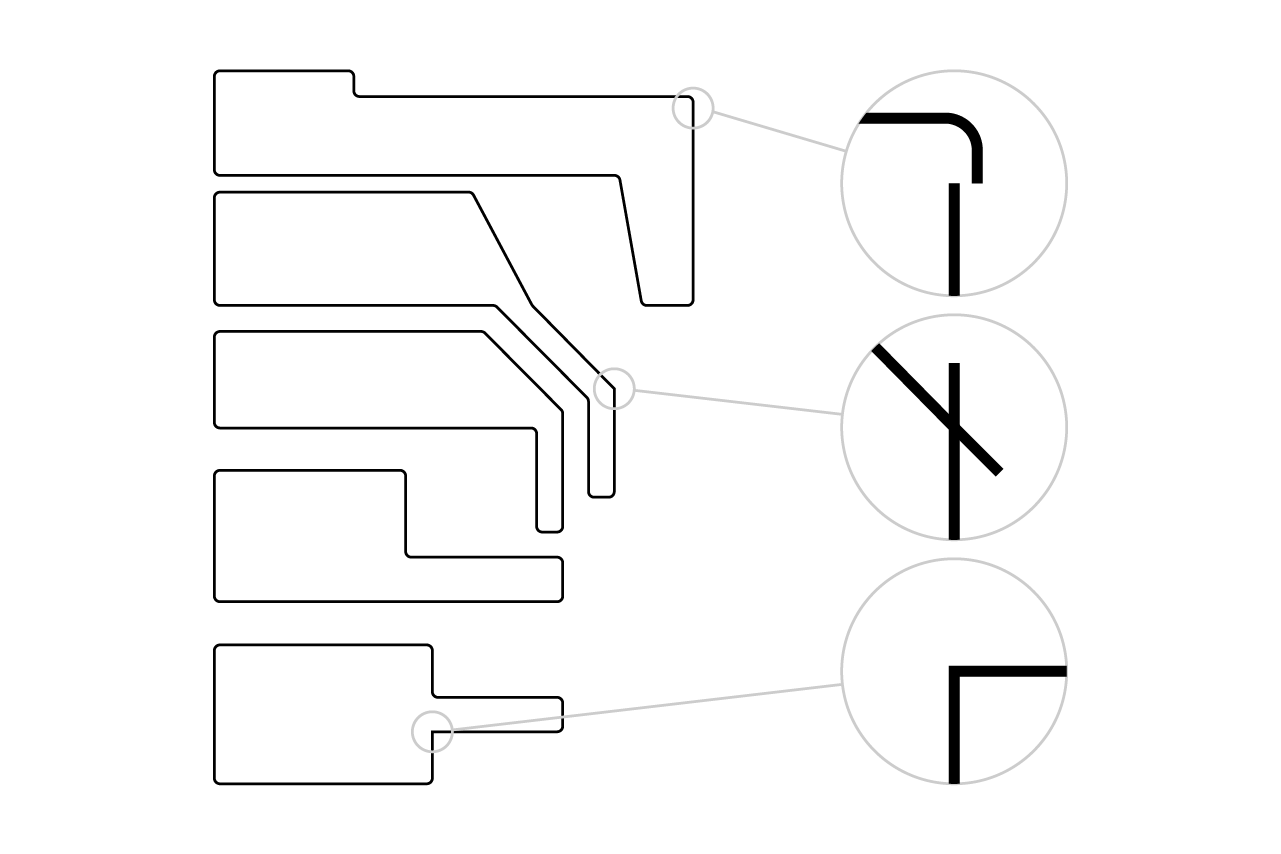

Strategy

The wire cut strategies available in Mecanic more or less cover all the requirements of the customers.

In some case based on the customer’s know-how, standard strategies or manufacturing are not enough, in this case Mecasoft offers support to create users personalized work strategies.

Mecanic allows to create a program based on two or more wire cut machines. The user can decide later for which one to create the NC code, maintaining the same machining strategy or sort properties.

Certification of the manufacturing

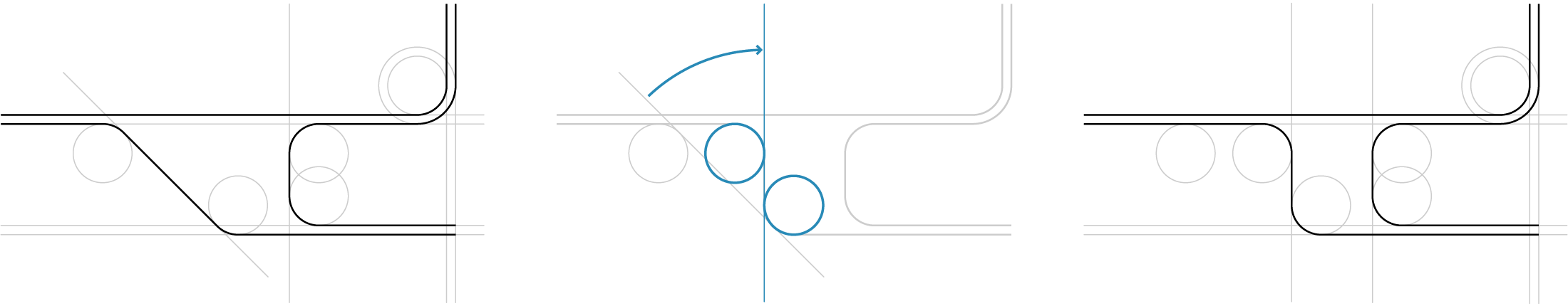

Simulation is carried out with the offsets of the selected technologies. All problems are announced and visualized.

For example, the undercuts can thus be discovered and avoided.

In this case the solution consists to use the Mecanic RMI (radius minimum) feature.